Micro Welders

AMADA’s micro welders support parts manufacturing in Japan and around the world.

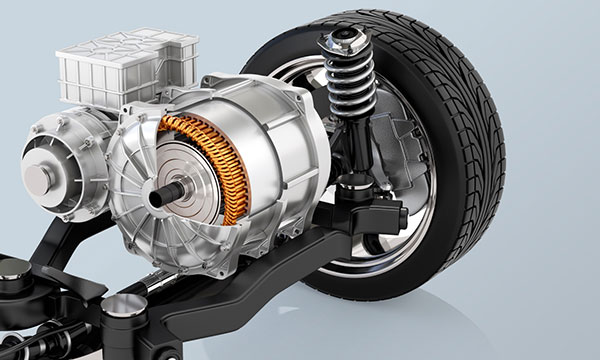

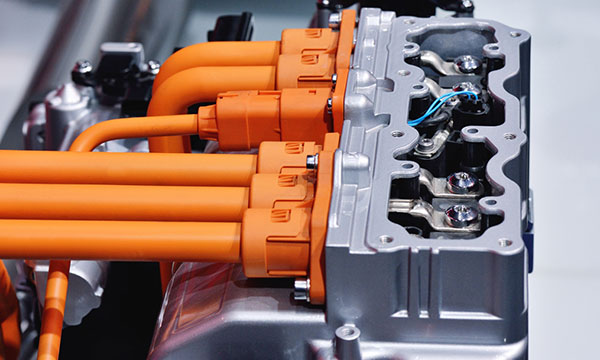

Our Micro Welding Division offers products broadly divided into two types of micro welding: laser welding and fine spot welding. Laser welding is a welding method that utilizes the heat generated by focusing an artificially produced laser beam. Fine spot welding, also known as resistance welding, uses resistance heat generated by passing a current through the workpiece. These are key technologies supporting an extremely wide range of manufacturing (parts production), including not only automotive parts such as engines, motors, inverters, and sensors, and electronic parts such as cameras, connectors, semiconductors, and integrated chips, but also batteries, communication parts, eyeglasses, jewelry, and more.

Where our micro welders are used

Products made with our micro welders

Micro welder lineup

-

Laser welders

AMADA’s laser welder lineup includes fiber laser welders suitable for motors and batteries, YAG laser welders suitable for electronic components, and others.

-

Fine spot welders

AMADA offers welding power supplies optimized for each application, such as transistor-controlled power supplies for electrical components and DC inverter-controlled power supplies for motors and sensors.