Metal Cutting Machines

These machines rotate tools affixed with saw blades to cut materials.

These machines are used in the initial sheet metal fabrication processes. They are broadly divided into two types: band saw machines, which cut by rotating a band-shaped blade, and circular saw machines, which cut by rotating a disk-shaped blade. AMADA offers a wide variety of machine bodies and blades to suit the hardness, size, and shape of the material to be cut.

AMADA is known as one of the few companies that develops and manufactures both machine bodies and blades.

Where our metal cutting machines are used

Products made from metal cutting machines

Metal cutting machine lineup

-

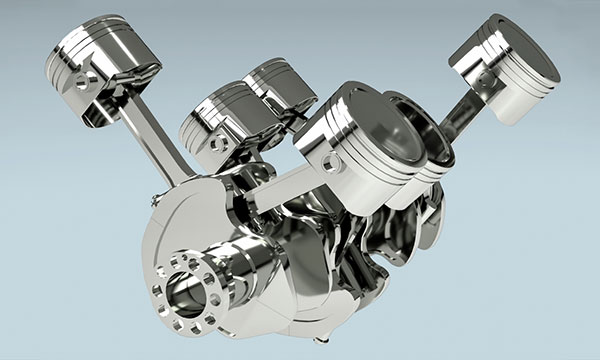

Band saw machines

These machines rotate band-shaped saw blades to cut materials. They are capable of cutting a wide range of materials, from small-diameter materials to large materials, and from general steel to difficult-to-cut materials.

-

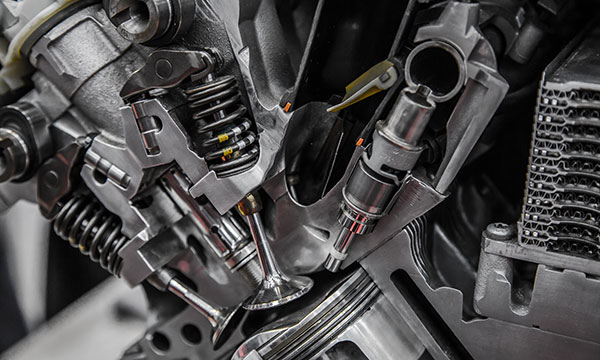

Circular saw machines

Circular saw machines use disk-shaped blades to cut materials. Compared to band saw machines, these are notable for greater accuracy and cleaner cut surfaces. They are used to cut small-diameter materials.

-

Rotary pipe cutters

Rotary pipe cutters shear pipes by pressing a disk-shaped cutter against the pipe.

-

Blades

These are broadly divided into two types: band-shaped blades for band saw machines and disk-shaped blades for circular saw machines. AMADA offers a wide variety of blade types to suit material quality, size, shape, and other factors.