Resolving Social Issues through Our Business

As an organization contributing to society through its business, the AMADA Group pursues the development of innovative products that address social issues and meet customer needs.

Based on the social issues our customers face in manufacturing, we have formulated a product development concept called “4ie,” which guides our activities based on four important keywords.

Diversity

Diversity

Enhanced support functions to help diverse individuals work efficiently and safely, regardless of their proficiency level

Nowadays, the workforce at our production sites is increasingly diverse in terms of age, gender, and nationality. However, conventional equipment is complex and relies heavily on skill and experience. For inexperienced operators, these complex operations can lead to work errors and reduced efficiency. Training costs have also become a significant burden in the field.

To address these issues, AMADA introduced AI-powered facial recognition cameras in its operation panels, allowing screen displays to be modified to suit the operator’s language and proficiency level. Guidance is displayed on the tablet as the operator carries out their tasks, making it easy to set processing positions for special shapes. In addition, heavily labor-intensive and experience-intensive tasks such as material feeding and tooling changes are also being automated. These improvements allow less experienced operators to work more efficiently and safely.

Improving labor productivity

Improving labor productivity

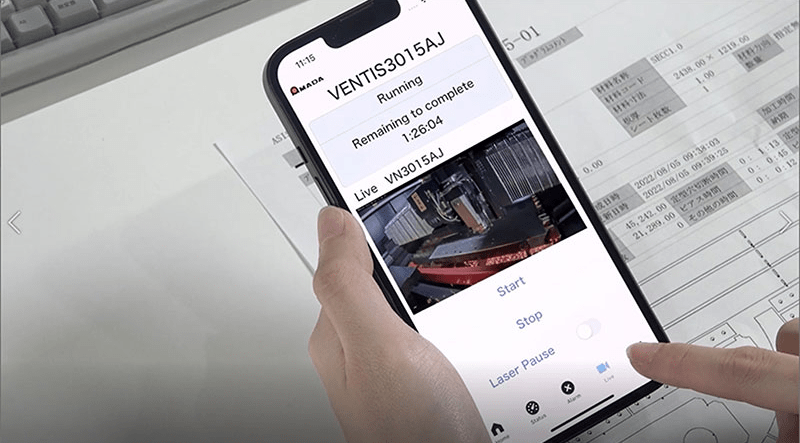

Remote confirmation and operation for efficient supervision of multiple devices

As demands build around the world for greater labor productivity and a better work-life balance, manufacturing floors are striving to reduce unnecessary work and improve machine utilization rates. However, each machine has many different operations, resulting in a number of flow lines, leaving workers somewhat overwhelmed at times by the machines. Especially when one worker is responsible for multiple pieces of equipment, having to move frequently to check the processing status or not noticing a halt has caused significant losses.

In response, AMADA has developed an application that lists the operating status of multiple machines on a handheld mobile device. This allows workers to check machine status from anywhere in the plant. The application supports more efficient workstyles by sending a notification when processing is about to complete or when an alarm is triggered, and by enabling remote start and restart of processing.

Addressing climate change

Addressing climate change

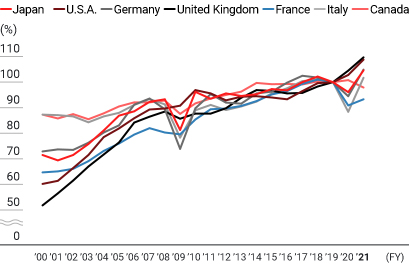

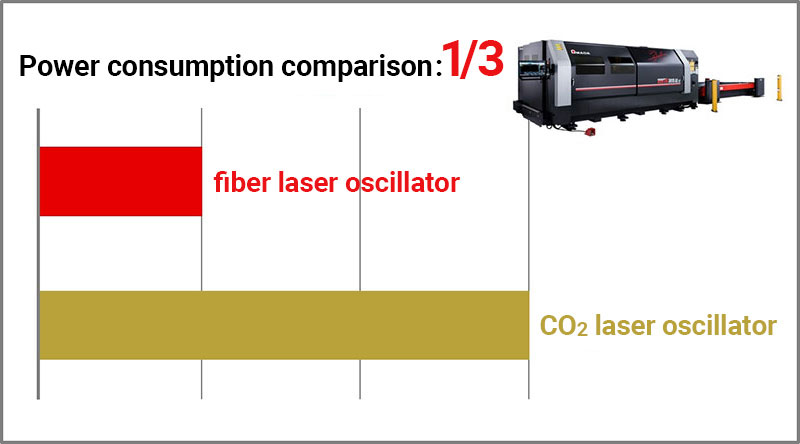

Supporting reduced environmental impact of products through visualization

At the Conference of the Parties to the United Nations Framework Convention on Climate Change (COP26), held in 2021, the major goal of achieving virtually zero greenhouse gas emissions (carbon neutrality) by 2050 was set, and countries are setting reduction targets to achieve this goal. As companies’ social responsibilities increase, environmental initiatives in daily production activities have become an important condition for becoming a company of choice.

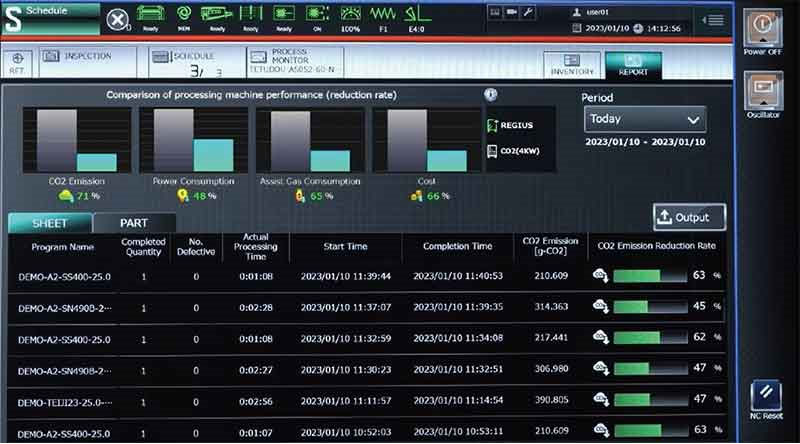

In response, AMADA has developed eco-friendly machines with significantly reduced power consumption. We have also developed a function to visualize the CO₂ emissions of manufactured products and the environmental impact of production activities, which can be compared with AMADA’s standard machines to display a comparative view of how eco-friendly any given processing is. Through coordination with digital transformation (DX) solution products, CO₂ emissions for the entire manufacturing process can be aggregated, with this information provided to the production management system.

In addition, for small and medium-sized manufacturing companies, we offer support services for obtaining Science Based Targets (SBT) certification, which indicates that a company’s greenhouse gas reduction targets are consistent with the goals of the Paris Agreement. In this way, we help to create environmentally sustainable production activities.

Greenhouse gas emission reduction targets by country

| Japan | 2030 target : 46%, with an aim to tackle 50% (Base year : Fiscal 2013) Long-term target : Carbon neutrality in 2050 |

|---|---|

| United States | 2030 target : 50~52% (Base year : 2005) Long-term target : Carbon neutrality in 2050 |

| EU | 2030 target : 55% (Base year : 1990) Long-term target : Carbon neutrality in 2050 |

| United Kingdom | 2030 target : 68% (Base year : 1990) Long-term target : Carbon neutrality in 2050 |

| China | 2030 target : Decrease of more than 65% per unit of GDP, lower absolute emissions (Base year : 2005) Long-term target : Carbon neutrality in 2060 |

Enhancing technological innovation

Enhancing technological innovation

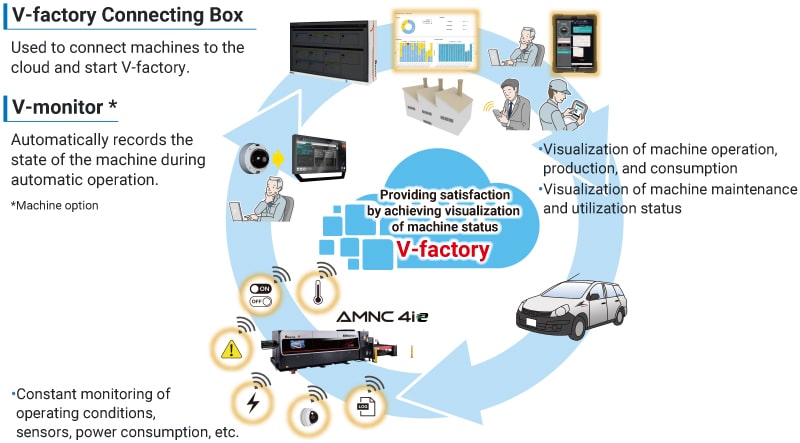

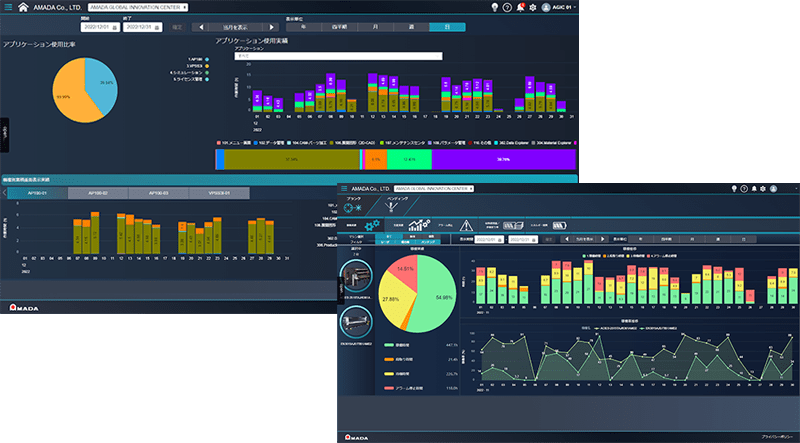

Connecting the entire factory with IoT to make manufacturing smarter

To build a sustainable and prosperous society in the future, it is essential to improve and develop industries through technological innovation. AMADA is actively making contributions to this important issue through the promotion of DX. One such contribution is in creating smart factories. Promoting the concept of the V-factory, everything in the factory, from machines to toolings and software, are connected via a network and linked to the AMADA IoT Support Center via secure communication technology. This makes it possible to digitize and share information on all manufacturing processes and visualize factory issues. As a result, factories can gain efficiencies in resources, time, and cost, promoting higher value-added manufacturing.