Research and Development

AMADA is engaged in research and development for cutting-edge technology to meet needs captured through direct sales and direct service.

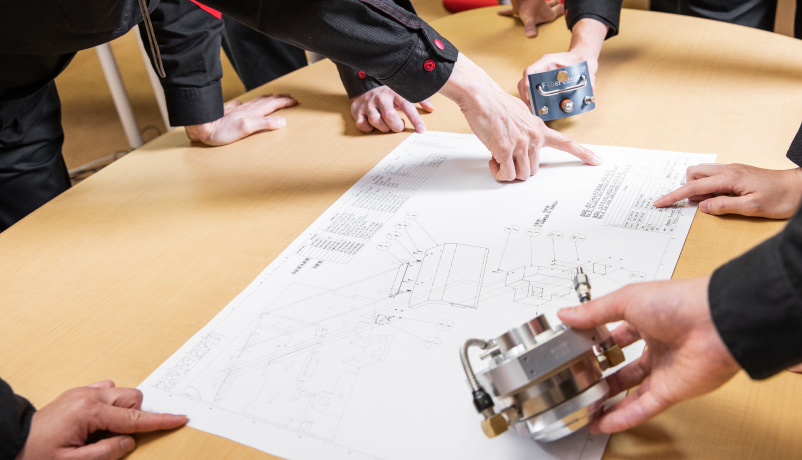

Research and development driven by direct sales and direct service

The AMADA Group develops technologies capable of contributing to problem-solving at a higher quality by identifying the diverse issues faced by its customers. In order to provide processing technologies that align with our customers’ needs, we currently develop products in a way that is rooted in regional characteristics and our customers’ production activities, at 16 development bases in Japan and overseas.

Furthermore, at the product planning, development, and procurement stages, we set clear goals for the environmental impact of our products and conduct evaluations at each step of development in order to launch products with industry-leading environmental performance.

Research and development track record

The AMADA Group maintains more than 1,000 patents at any given time in Japan and overseas. We actively invest in intellectual property, filing more than 100 new patent applications per year, to secure a competitive advantage in the global market. Intellectual property rights secure the technologies and brands we have generated through research and development and we strengthen checks and balances against potential competitors through the formation of a portfolio. With this system, we support the laser, automation, and service businesses, core businesses for the AMADA Group’s growth strategy.

Approx. 1,300

¥6.2 billion

More than 100 per year

Research and development addressing customers’ production issues

The AMADA Group conducts research and development on a wide range of products, including machines, automation systems, control devices, software, toolings, and saw blades, to provide a one-stop solution to customers’ production issues.

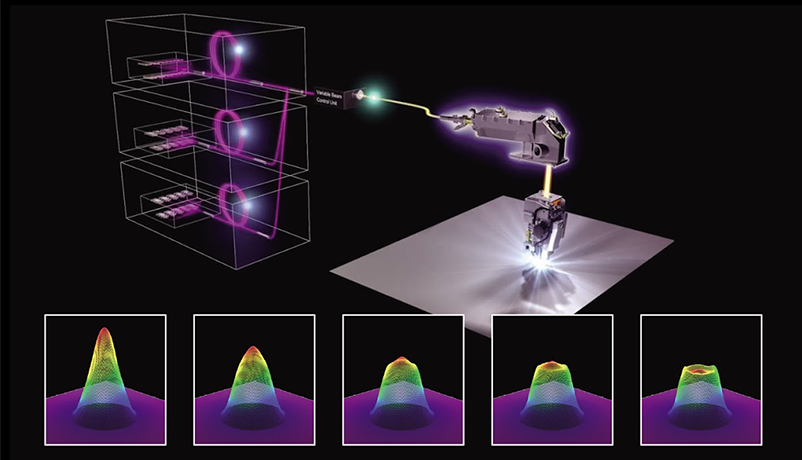

Cutting-edge laser technology

In laser technology, an area of increasing demand, we have developed a variety of oscillators in-house, including fiber lasers, YVO4 lasers, YAG lasers, and direct diode lasers.

We have also developed proprietary technologies to control the shape and trajectory of laser beams, and have established a wide range of processing technologies for cutting, welding, marking, soldering, and laminated shaping.

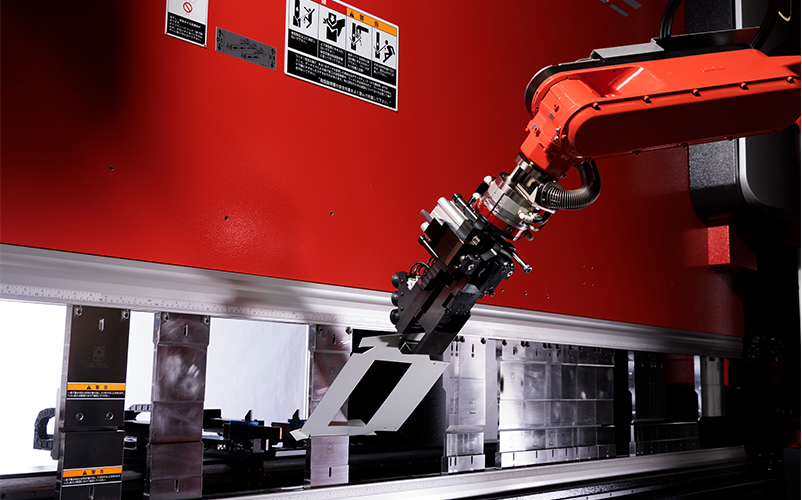

Automation and labor-saving technology

In the metalworking field, workers commonly handle heavy items, including materials and toolings, and must engage in setup work that requires extensive experience.

To relieve these burdens, we have made automation and labor saving an early priority, and are currently developing our own autonomous mobile robots (AMRs) to automate inter-process operations.

Control technology

AMADA has been working to automate bending processes since the 1980s. Despite its challenging nature, we have successfully automated bending by developing advanced coordinated control of processing machines and peripheral equipment. Furthermore, the system now automates setup work to accommodate high-mix, small-lot production. Since the 1990s, AMADA has been working to automate the even more challenging welding processes for thin sheets, and has developed a compensation system using AI. Every day, we continue to develop our technologies to ensure universal usability.

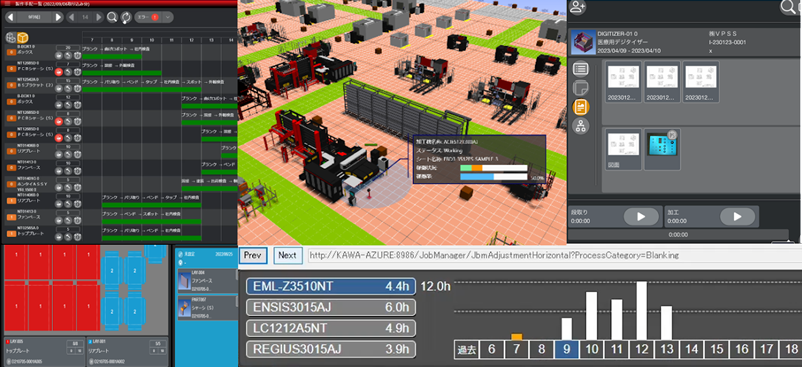

Software

In machining, it is important to create accurate processing programs. AMADA develops unique automatic programming systems that use computer simulations to generate accurate programs.

We also develop systems for manufacturing DX that visualizes and optimizes production progress and aids productivity improvement at our customers’ plants.