V-factory

AMADA’s IoT solution, V-factory

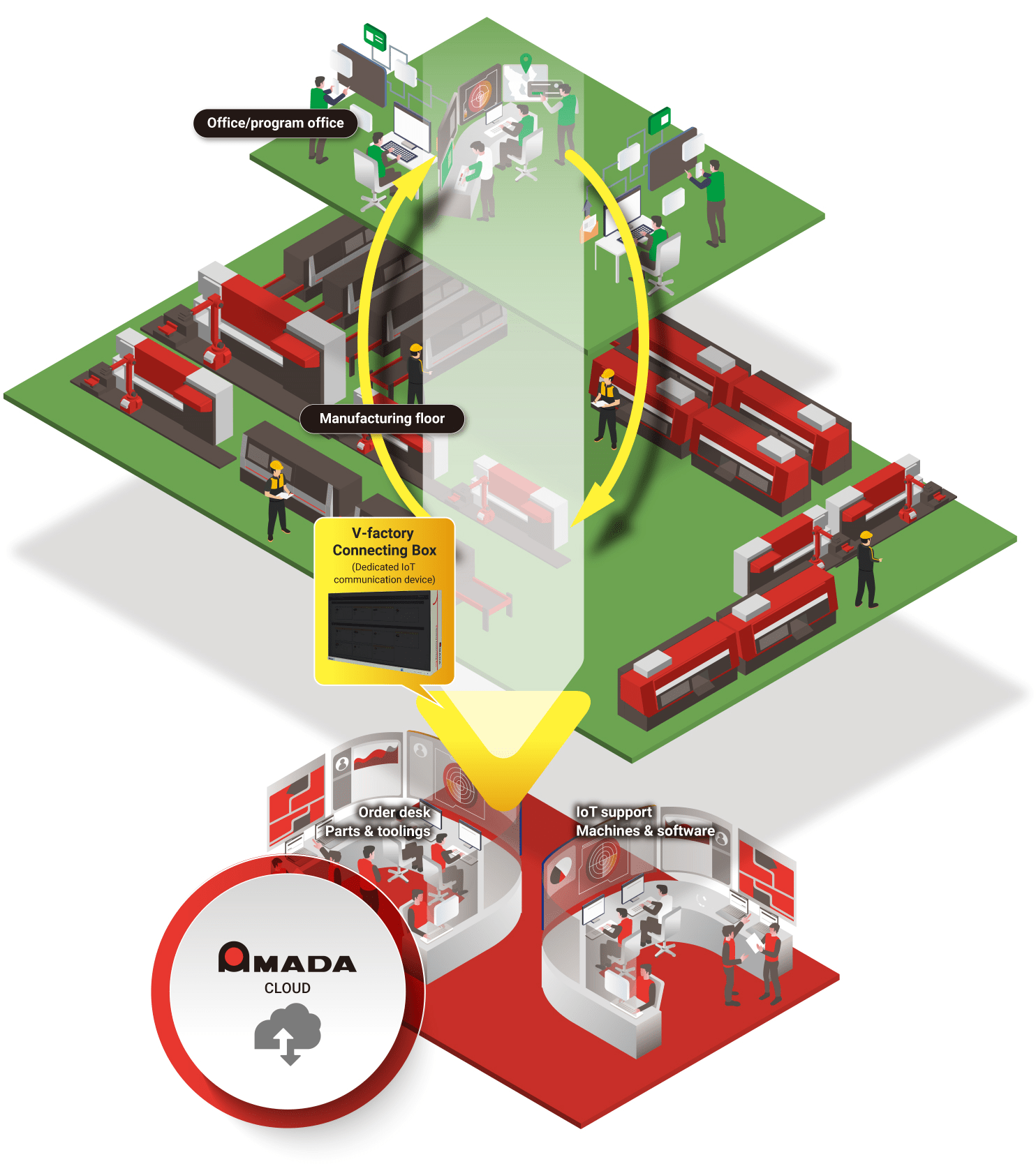

V-factory is a system that utilizes IoT to visualize any issues in real time in each factory and realize high-value-added production.

The system can share the same information to all employees involved in production, from factory management to operators, leading to quick problem solving. This unlocks the creation of high added value, such as increased productivity, reduced costs, and increased motivation.

This IoT solution provided by AMADA utilizes data to transform factories toward consistent growth.

Service Details

Two V-factory pillars

V-factory utilizes IoT technology to transform factories into smart factories capable of quickly adapting to changes in our customers’ business challenges through its two pillars: IoT products and IoT support systems, the latter provided as part of AMADA’s support systems.

V-factory creates new value for our customers by fusing the virtual with the real, equipped with our cutting-edge processing and networking technologies.

-

Utilization management -

Customer support center

・Monitoring (utilization monitoring)

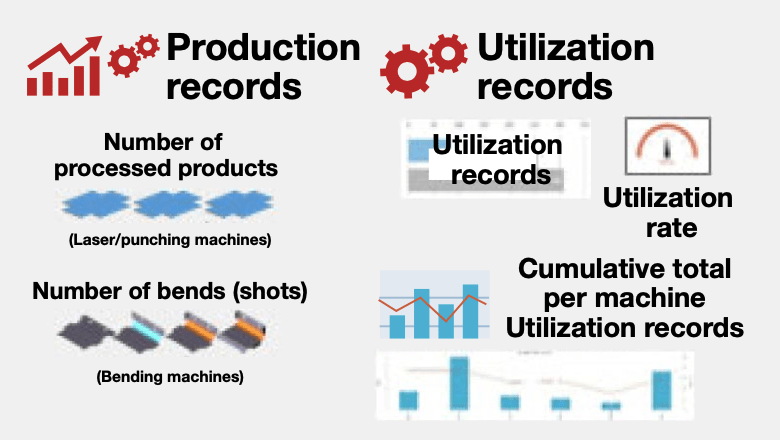

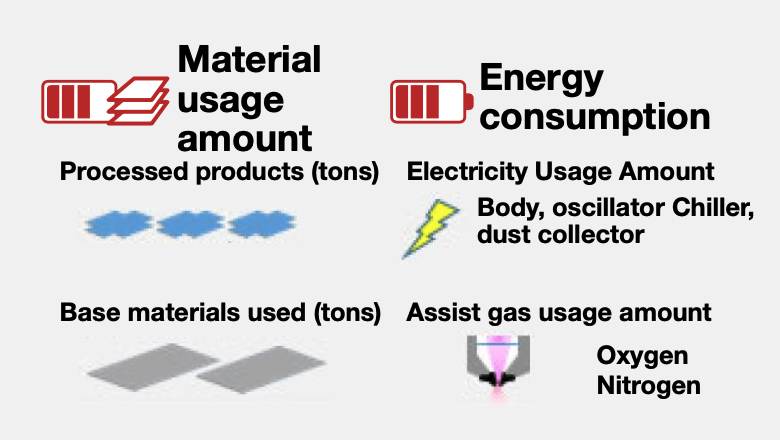

Operating information is uploaded in real time from machines, software, and equipment connected to V-factory, allowing users to check utilization status remotely via the internet. Users can also access the machine’s production performance and utilization rates, and check for any problems in production or utilization. In addition, it shows how much material and energy is used by all machines connected to V-factory, helping to reduce waste in production.

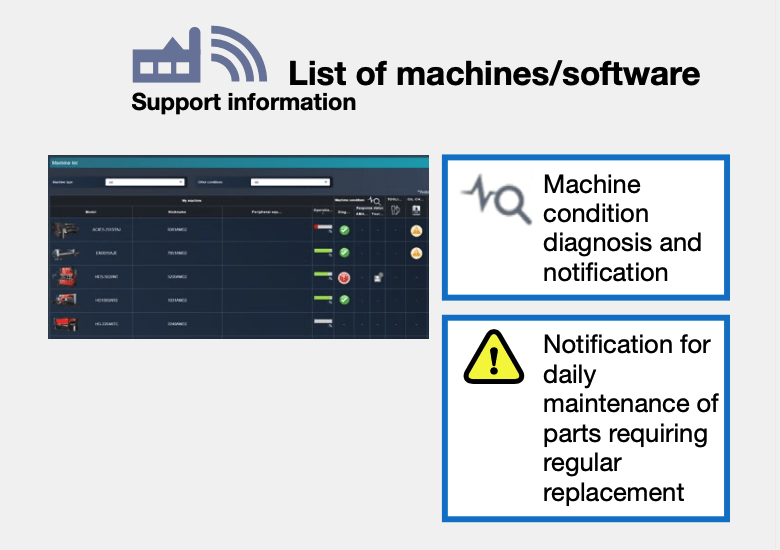

・IoT support (operational support)

V-factory connects to AMADA’s customer support center to remotely diagnose machine conditions and perform preventive maintenance. It offers swift failure recovery through remote support in the event of an unexpected outage.

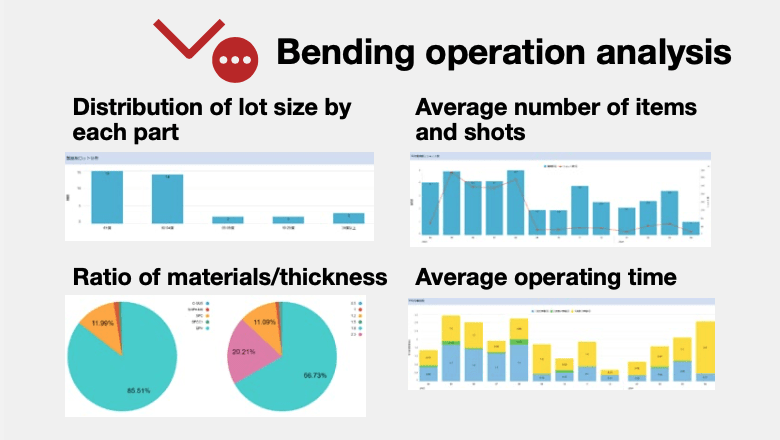

V-factory can also help to improve productivity through consulting services that provide reports analyzing operational data and offer suggestions for operational improvements.