Fine Spot Welders

Fine spot welding (resistance welding) is a joining method using heat generated from resistance caused by placing electrodes in contact with workpieces to apply force and let current flow into workpieces.

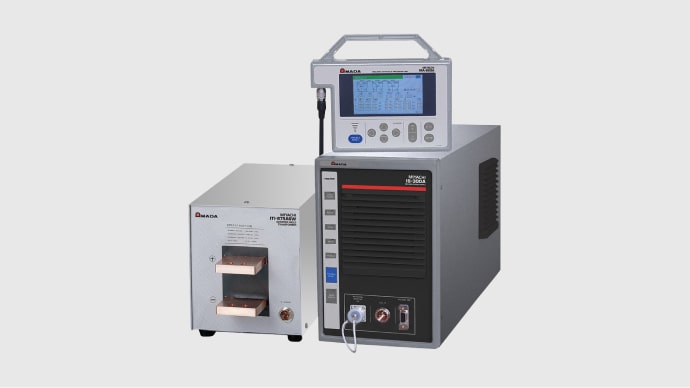

Transistor-controlled welding power supplies

These units offer ultra-precise welding due to transistor control which enables reducing splash by finely adjusting the weld current.

DC Inverter controlled welding power supplies

These units supply continuous power efficiently, because, unlike an AC-type power supply, it does not have any current downtime. Consequently, it offers a short weld time with excellent thermal efficiency, resulting in few heat-affected areas, and low power consumption. As it can be used with small welding transformers, it is suitable for a system integration.

AC Inverter controlled welding power supplies

These units are not only available inverter-type features such as an excellent thermal efficiency and stable weld quality, but also available a minimal Peltier effect (polar effect) due to the alternating current AC-current welding transformers are available. It is ideally suited to fusing.

AC controlled welding power suppies

These unit are the most commonly used type of welding power supply. With a simple structure, it is easy to use, offers excellent durability, and is inexpensive. It is widely used for welding materials made of iron, a material that is relatively easy to weld.

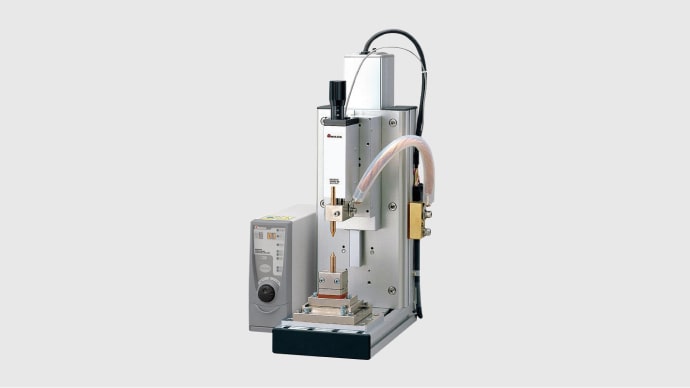

Weld heads

Weld heads, which are installed in fine spot welders, hold electrodes and perform welding by applying force to workpieces.

Checkers and Testers

Weld heads, which are installed in fine spot welders, hold electrodes and perform welding by applying force to workpieces.

Pulsed TIG Welders

DC type pulsed TIG welders are the perfect solution for arc welding of precision and minute parts. This is because welding can be finished with small heat-affected area.

Pulsed Heat Controller

Pulsed heat controller controls pulsed current to obtain optimum heat for bonding multiple parts. Real-time temperature feedback from a thermocouple attached to a thermode enables to adjust heat temperature in detail and precision performance according to the programmed heat profile can be done.

Systems

AMADA provides not only technologies for automation and equipment but also system solutions that integrate welding and processing expertise.