Laser Welders

AMADA’s laser welder lineup includes fiber laser welders suitable for motors and batteries, YAG laser welders suitable for electronic components, and others.

Fiber laser welders

Due to their beam characteristic being different from that of a YAG laser and their use of CW mode, fiber laser welders provide high-quality fine welding and high-speed seam welding.

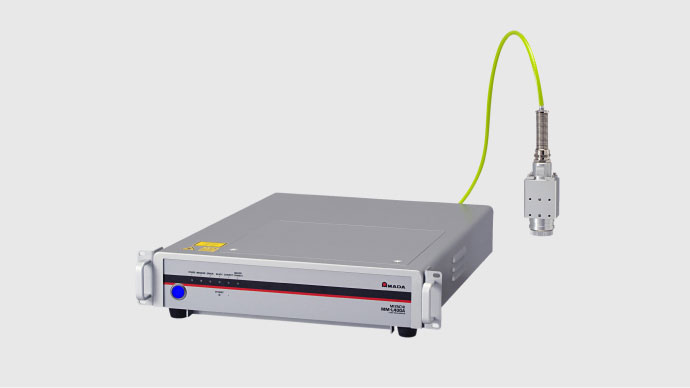

Pulsed fiber laser welders

This series of laser welders provides high-quality, high-stability welding by using a new type of pulsed fiber laser. As they are energy-saving and use a chiller-free air-cooling system, these welders can reduce operating costs.

YAG laser welders

Our standard YAG laser welders series.

YAG SHG green laser welders

Our YAG SHG green laser welders enable stable welding for copper and gold, which are difficult to weld due to their higher reflectance to fundamental wavelength of YAG laser.

Direct diode laser welders

Light from the laser diode is used directly for thermal processing without passing through a YAG or YVO4 crystal in the laser unit. Fitted additionally with the new Active heat control™ function, this welder performs quality plastic welding and soldering at low cost in an environmentally friendly manner.

Laser scanning systems for welding

Using a digital galvoscanner, our laser scanning systems provide precision, high-speed, and multi-spot welding without the need to move the workpiece and/or use an XY table.

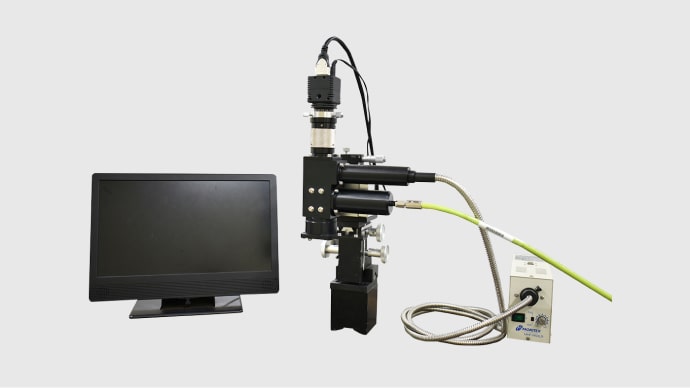

Laser weld monitors

These monitoring devices measure the light generated at the welding point and detect welding abnormalities based on changes in light intensity. Not only do they resolve the issue of labor-intensive inspections and associated costs, but they also contribute to preventive maintenance, keeping defective products from reaching the market.

Focusing heads and optical fiber

These head units efficiently collect laser light emitted from the optical fiber. The broad lineup for these output units includes a head assembly with a charged-coupled device (CCD) camera.

Systems

AMADA provides not only basic technologies for automation and equipment but also system solutions that integrate welding and processing expertise.