Management of Chemical Substances

Basic policy

The AMADA Group is taking stronger efforts regarding regulated chemical substances to ensure that customers can use its products with peace of mind.

We will practice appropriate management of chemical substances to ensure that we provide our customers with safe machines made of safe materials.

Managing chemical substances contained in products

Addressing chemical substances contained in products

At the AMADA Group, we control chemical substances contained in major products through management via the chemSHERPA*1 scheme in accordance with regulations as appropriate by country; for Japan, this is as Class I Specified Chemical Substances under the Act on the Regulation of Manufacture and Evaluation of Chemical Substances; for the United States, the TSCA*2; for Europe, the RoHS*3 Directive, POPs*4 Regulation, and REACH*5 Regulation; and for China RoHS*6.

- *1Chemical information SHaring and Exchange under Reporting PArtnership in supply chain

- *2Toxic Substances Control Act

- *3Restriction of Hazardous Substances

- *4Persistent Organic Pollutants

- *5Registration, Evaluation, Authorisation and Restriction of Chemicals

- *6Administrative Measure on the Control of Pollution Caused by Electronic Information Products (China RoHS)

Management of chemical substances for oils and fats

AMADA brand hydraulic oil, lubricating oil, cutting oil, and other oils and fats sold by the AMADA Group are compliant with regulations related to contained chemical substances. In addition, hazards are classified based on the GHS*7 and the results are listed in the SDS*8.

- *7GHS: Globally Harmonized System of Classification and Labelling of Chemicals

- *8SDS: Safety Data Sheet, a document containing hazard and toxicity information on chemical substances to be issued when a product is transferred or provided to other businesses

Chromate treatment

For the surface treatment of mechanical parts designed in-house, we have shifted from hexavalent chromium, which has a large environmental burden, to the more environmentally friendly trivalent chromate.

Safety management and control of chemical substance use in the manufacturing process

In addition to products supplied to customers, all of the AMADA Group’s manufacturing plants are working to reduce the amount of regulated chemical substances during the manufacturing process, based on the Groupwide Medium-term Environmental Plan.

Reducing chemical substances by introducing new paint technology (Fujinomiya Works)

By applying the new Nitrotherm spray system utilizing nitrogen gas, paint transfer efficiency improved dramatically at the Fujinomiya Works. As the heated ionized nitrogen lowers the paint viscosity, much less diluting solvents are necessary.

Following the introduction of this new technology, paint usage was reduced by 27%, volatile organic compound (VOC) emissions by 35%, and paint sludge (industrial waste) by 25%.

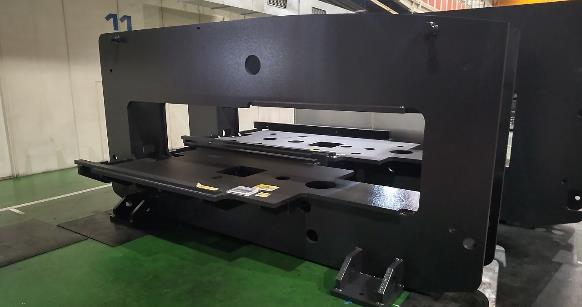

Reducing paint usage by adjusting paint composition

In the frame painting process for punching/combination and bending machines, we adjusted paint composition and quantified paint use, implementing measures to reduce the amount of paint used. As a result, processes that previously required three coats of paint can now form the same pattern with only two coats of the adjusted paint composition. This resulted in a 14–24% reduction in paint usage.

Green procurement

The AMADA Group regards green procurement, the procurement of materials with low environmental load, as one of its important environmental conservation activities.

AMADA has established the AMADA Group Green Procurement Guideline for green procurement and is advancing environmental management, including for its suppliers, to provide customers with products that have lower environmental load.

In recent years, environmental laws and regulations concerning chemical substances have become increasingly strict around the world.

The AMADA Group will disseminate its approach and requirements for the management and communication regarding chemical substances in products in the supply chain in accordance with the Green Procurement Guidelines and act accordingly.

We evaluate suppliers through a green procurement partner survey as a method of confirming the status of their implementation of the AMADA Group’s requirements.

Depending on the resulting evaluation level, we will request that some suppliers make improvements to their management systems, or even conduct an audit.

Through these efforts, we also support environmental risk management and the promotion of appropriate chemical substance management at our suppliers.

We thank all of our suppliers and stakeholders at large for their cooperation.

AMADA Group Green Procurement Guideline

Details of green procurement management are stipulated in the AMADA Group Green Procurement Guideline, linked below, and other documents.

| AMADA Group Green Procurement Guideline | English version (350KB) |

|---|---|

| AMADA Group List of regulated chemical substances | English version (611KB) |

| Green procurement partner survey | English version (157KB) |

- The Green Procurement Guideline is scheduled to be revised into the Sustainable Procurement Guideline. This revision is planned to include not only legal compliance and environmental considerations but also respect for human rights and social contributions.