Stamping Presses

Stamping presses form materials such as sheet metal into the shape of dies by applying pressure. The advent of the latest servo-drive stamping presses enables high-value added forming.

Digital AC servo presses

Digital electric servo-drive stamping presses are the latest environmentally friendly press machines that reduce power consumption, oil use, and noise. The fusion of a dedicated servo-motor and a proven crank mechanism opens up a world of high productivity and high-value added forming.

Link Press

Our original link mechanism reduces blanking impact by working slowly around the bottom, enabling high-quality pressing without reducing productivity with its fast-approach, fast-return operation.

Crank Press

These are general-use, workhorse stamping presses. They feature a high-rigidity frame and six-sided guide for the slide with an eccentric load-resistant structure, and a unique crank mechanism to drive the slide for high precision, high production, and space saving to meet a wide range of needs.

Knuckle Link Press

Knuckle link presses are link presses with a knuckle mechanism. These presses feature an optimized frame bed structure with a high-rigidity structure for the column, slide, and crown.

Conventional system upgrades

The integrated frames feature the shortest possible line structure and an easy-to-use, stand-alone operation panel.

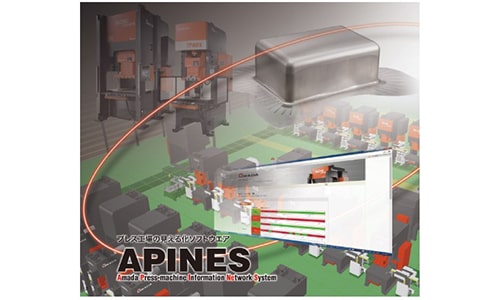

Software for Stamping Press Machines

Software dedicated to stamping presses that enable visualization of operating status and maintenance information through a digital network.