The AMADA Group in Everyday Life

Things made using the AMADA Group’s machines support all of our lives in various places, including in our homes and in the towns where we live and work.

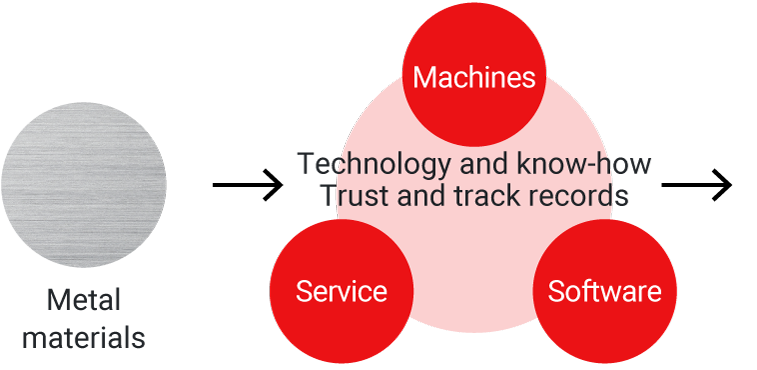

How metal parts are made

Metal materials undergo various processes such as cutting, bending, welding, and forming before they become parts and can be incorporated into a final product. The AMADA Group develops the machines and software that perform this metalworking and provides 24-hour service to the manufacturers using them.

❶ Offices

From office fixtures such as lockers, cabinets, and chairs to electronic devices such as computers and multifunction printers, metal parts of various shapes and sizes are used for a wide range of applications.

❶Elevators

In these boxes that ferry people up and down, most of the walls, doors, control panels, and power components are fabricated with sheet metal and presses. The specifications vary depending on the building in which the product is used, meaning that support for variable-mix, variable-lot production is necessary.

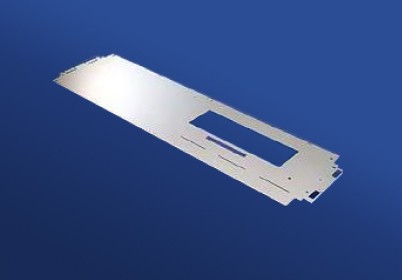

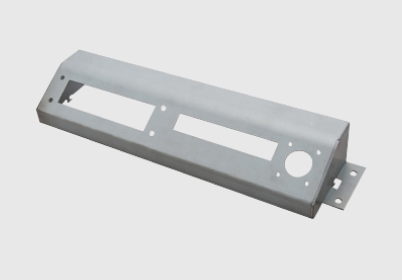

❷Office multifunction printers

Nearly all of the metal parts inside of printers are made via sheet metal fabrication. Technology to remove burrs from cutting or drilling in component metal is essential to prevent paper from getting caught in the printers when printing.

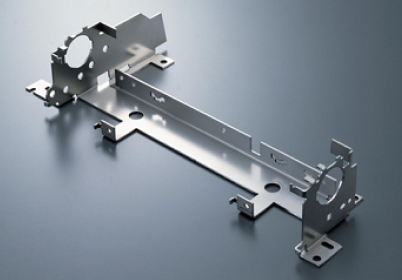

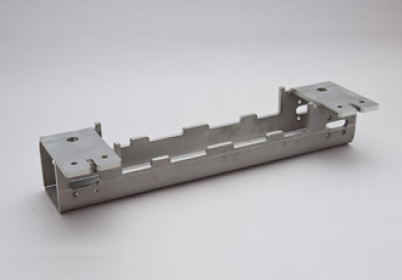

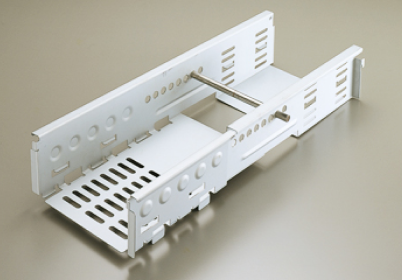

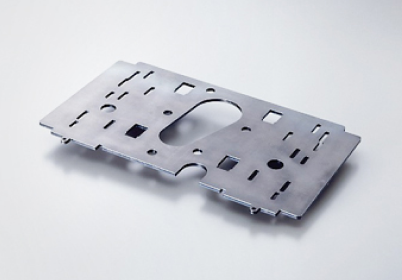

❸Computers

A number of metal parts can be found inside computers, most of which are made via sheet metal fabrication and stamping press processing. As products become smaller and lighter, the processing of parts also needs to be more precise.

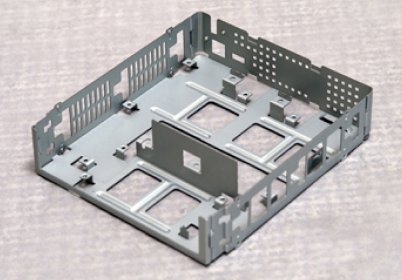

❹Steel fixtures

Nearly all lockers, cabinets, desks, and other fixtures are made with sheet metal fabrication. Successful assembly of these steel fixtures requires that all drawers, walls, and other elements be accurately processed without gaps or distortion.

❷ Train stations

In addition to train interiors and exteriors, metal parts are used in various places in train stations, such as platform doors, automatic ticket gates, and ticket vending machines, which require high durability in order to support people’s daily movement.

❶Train cars

Because of the need for durability as well as light weight, train cars are made of aluminum and/or stainless steel. Most metal parts such as instrument panels and switches in the car, doors, and cab are created from sheet metal fabrication or stamping press processing.

❷Platform doors

Platform doors have become increasingly popular in recent years as a safety measure to prevent accidents involving falls from platforms or contact with trains. Various kinds of processing, including sheet metal fabrication, stamping pressing, cutting, and machine tool processing is performed for the exterior, interior framework, and motor parts that power the door mechanisms.

❸Automated ticket gates

The physical gates that open and close when people pass through are made of resin, but the main housing is made of sturdy metal due to the gates containing precision devices that read integrated chips from cards. Sheet metal is processed by cutting and bending metal sheets into smooth curves.

❹Ticket vending machines

Production via sheet metal fabrication is well suited to handling the varying specifications between railway operators for the exterior design and parts of these machines. Advanced precision sheet metal technology and deburring for a smooth finish are essential for parts in the flow paths for train tickets, paper currency, and coins, in order to move them around the machine accurately and at high speed.

❸ Convenience stores

Many processed metal parts are used in devices closely connected to our daily lives, such as cold-storage showcases, ATMs, and commercial-use microwave ovens.

❶Cold-storage showcases

Most cold-storage showcases are made of stainless steel in the interest of cleanliness. Their frames and shelves are made of thin, long stainless steel sheets bent by a sheet metal fabrication machine.

❷ATMs

ATMs are made to robust specifications for security purposes, and their exteriors are made of sheet metal fabricated parts. ATMs are a commonly thought-of kind of product made largely with sheet metal fabrication.

❸Trash cans

Increasingly, trash cans are being made of stainless steel for their cleanliness, design, and durability. These are mainly manufactured through sheet metal fabrication.

❹Commercial-use microwave ovens

Commercial-use microwave ovens are covered with a sturdy exterior, finished through sheet metal fabrication. The interiors also feature a number of parts made with precise sheet metal fabrication.

❹ Homes

Metal parts are used in a range of products found in everyday life, such as air conditioners, televisions, cell phones, and refrigerators. In these products, AMADA’s processing technology contributes to safety, security, and convenience.

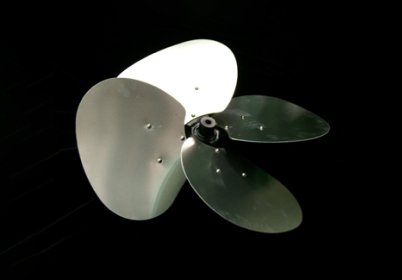

❶Air conditioners

For split units, metal parts inside the main unit and the exterior of the outdoor unit and fans are created from sheet metal fabrication or stamping press processing. Outdoor units are mainly made of aluminum and copper because they must be durable to resist corrosion even when exposed to the elements.

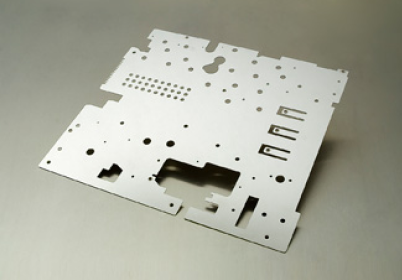

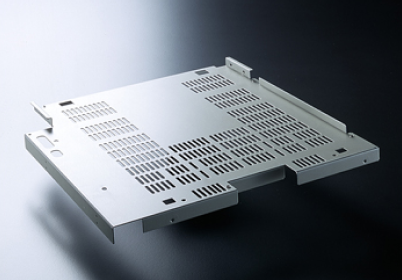

❷DVD players

DVD players contain precision recording media equipment, and are therefore protected by a sturdy metal case. Fine holes to release internal heat are made through sheet metal fabrication.

❸Tableware

Most common metal tableware items, such as metal tumblers and stainless steel spoons and forks, are made through stamping pressing.

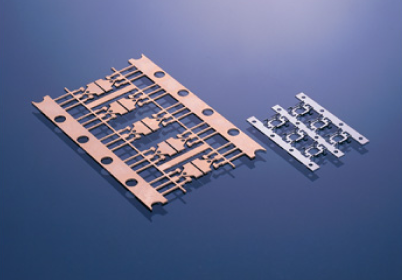

❹Cell phones

Metal parts inside the main body are created from sheet metal fabrication or stamping press processing. In order to process thin and compact parts with high precision and strength, advanced processing technology is required in addition to machine performance.

❺ Hospitals

Metal parts are also used in MRI and CT equipment, medical stents, and other devices that support advanced medical care. The AMADA Group’s high-precision, high-quality metalworking technology is indispensable for advanced manufacturing.

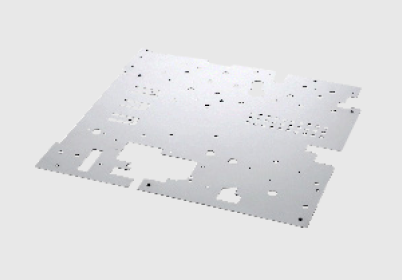

❶MRI/CT equipment

Various items made with sheet metal fabrication, including thin sheets and thick plates, are used for the frame and housing that support the MRI and CT main units.

❷Surgical lighting

Lightweight and strong sheet metal fabricated parts are used for parts that hold the light bulb and the adjustable arm.

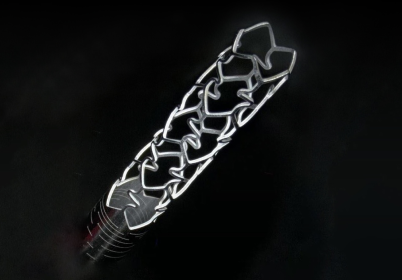

❸Stents

Stents* that secure blood flow are made of stainless steel, which is strong and resistant to corrosion, and are processed by micro laser cutting.

* A metal mesh tube of 2 to 3 mm in diameter that is implanted in a blood vessel. Stents are mainly used to dilate narrowed parts of blood vessels.

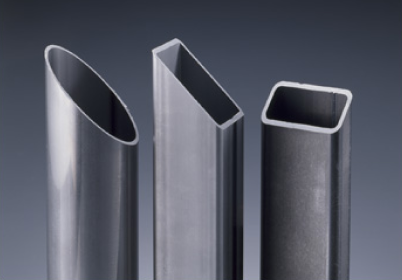

❹IV stands

Cutting, drilling, and other processing is used to make pipes that form the framework of the stands.