The AMADA Group’s History

The AMADA Group has always supported the manufacturing of society and its customers as a global manufacturer of metalworking machinery. Going forward, we will continue to innovate and take on challenges to contribute to our customers and society, and aim for further growth.

1946

Founded with a single fire-charred lathe

Isamu Amada, who was 32 years old at the time, opened a privately owned and modest machine repair shop using a lathe left over from a munitions factory after the war. This was the foundation of the AMADA Group, all originating with a single fire-charred lathe.

1955

Successfully develops the first domestically produced machine, our first step as a machine manufacturer

We took on the challenge of domestically producing band saw machines, which were already in widespread use in the West. The first unit, completed within three months of the start of design, was well received for performance that was on par with imported machines. This was the first step for the AMADA Group as a machinery manufacturer.

1960

Building business through the industry’s first demonstration car sales

AMADA began sales via demonstration cars, which would carry machines to customers for demonstrations. This creative sales approach later evolved into exhibition hall sales and then into today’s engineering proposals utilizing our Technical Centers.

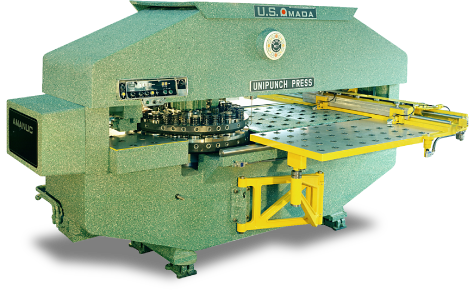

1971

An international bestseller is born

U.S. AMADA LTD. was established in the United States to absorb cutting-edge technology in sheet metal fabrication. The NC turret punch press (NCT) developed by this subsidiary was well received worldwide as a revolutionary product improving drilling precision, which was considered one of the biggest challenges at the time.

1980

Commercializes laser processing, building the foundation of today’s laser technology

At a time when lasers were not yet widely used, AMADA focused on lasers as an innovative sheet metal fabrication technology that did not require metal tooling, and succeeded in commercializing a laser machine for cutting applications. The accumulation of these technologies from this period has formed the foundation of today’s laser technology.

1990

Exceeds revenue of ¥200 billion

In the 1980s, AMADA worked to produce products outside Japan through efforts such as setting up production companies in the West, including in the United States and France. As business expanded, revenue grew from ¥100 billion in 1982 to more than ¥200 billion in 1990. In the 1990s, AMADA launched a full-scale expansion into Asia, including the establishment of a series of sales and production companies in China, solidifying its path to becoming a global company.

2003

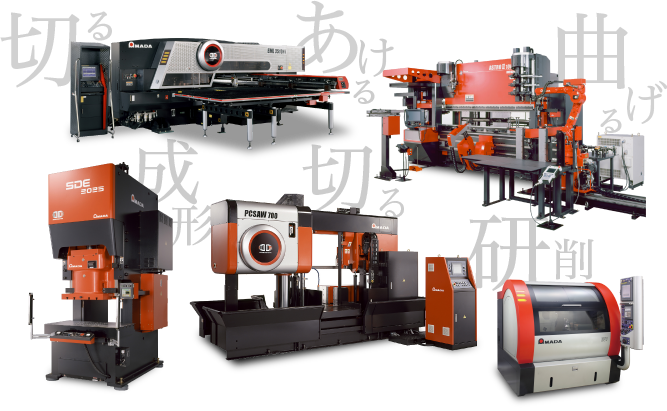

Becoming a comprehensive manufacturer of metalworking machines

The Group was reorganized, creating an integrated manufacturing and sales structure. This laid the foundations for AMADA becoming a comprehensive manufacturer of metalworking machinery, offering a lineup of metalworking products, together with software, peripheral equipment, and maintenance services.

2010

Becomes the world’s first machinery manufacturer to develop its own fiber laser oscillator

AMADA succeeded in developing a fiber laser oscillator in-house for the first time in the world as a machinery manufacturer. By featuring a fiber laser, a next-generation technology replacing CO2 lasers, this oscillator unlocked the manipulation of difficult-to-process materials and allowed us to offer energy-saving proposals capturing fibers lasers’ energy efficiency, further enhancing our total solution capabilities.

2013

Acquires Miyachi Technos Corp. to gain strengths in lasers

AMADA acquired Miyachi Technos, a manufacturer of laser and fine spot welders with strengths in micro welding and processing. By fusing the two companies’ technologies, we successfully evolved our laser technology further.

2015

Exceeds revenue of ¥300 billion

AMADA launched the ENSIS series of fiber laser machines, answering the continuous evolution of this field by incorporating its unique and innovative technology. Global sales volume accelerated and revenue exceeded ¥300 billion.

This new series of machines not only meets our customers’ needs for variable-mix, variable-lot production but also contributes to cost reductions through energy conservation and reduction of environmental impact.

2018

AMADA releases its V-factory IoT solution, advances smart factories

AMADA launched full-scale development of V-factory, an IoT solution for sheet metal factories. This solution visualizes the operational status of our customers’ metalworking machinery in real time. In addition, AMADA is able to help boost customer productivity with its IoT-based support system that remotely monitors our customers’ machines to ensure no unexpected outages and provides quick response to any outages that may occur.

2018

AMADA expands its business through proactive M&A, strengthening its ability centered around metalworking to meet diverse needs

In response to the growing need for increased productivity and automation at production sites, AMADA acquired a manufacturer of automation systems for metal stamping processing, establishing a system unlocking the provision of total solutions for stamping presses and automation systems.

AMADA also acquired a North American band saw manufacturer to expand its sales channels and product lineup.

2023

Striving to co-create the future with customers at the AMADA GLOBAL INNOVATION CENTER (AGIC)

AMADA opened the AGIC as “a place for co-creating the future of metalworking.” This center serves as a hub for the worldwide dissemination of AMADA’s work toward future-oriented manufacturing and creating innovation.

We aim to be a true partner that continues to take on challenges together with our customers in order to innovate in their manufacturing.

Dive deeper into AMADA’s history