Sheet Metal Processing

- LCG-3015

- LC-αⅤ Series

- Quattro

- System Upgrade

System Upgrade

Fork pallet changer (ASF/ASFH)

- Shortest cycle time consistent with high-speed fiber laser cutting (ASFH).

- Long continuous operation with a stack of materials on the single-pickup unit.

- The fork unit automatically unloads and stacks processed sheets.

- The shelves can be configured flexibly to meet the requirements of customers.

Pallet changer (AS)

- Long continuous operation is achieved with 10 shelves of processing pallets (a maximum of 15 pallets).

- Pop-up ball transfers facilitate the setting of worksheets and the sorting of parts.

- Microjoint-less processing is achieved.

Manipulator (MPL)

- Long continuous operation with a stack of materials on the single-pickup unit.

- The fork unit automatically unloads and stacks processed worksheets.

- The second station makes it easy to process manually inserted worksheets.

- The manipulator can be easily connected with the automated material storage and retrieval system MARS.

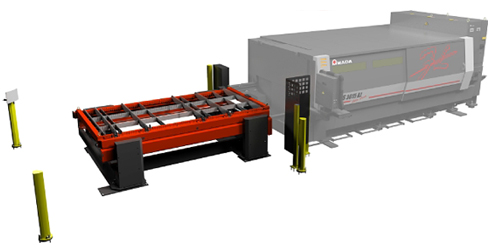

Shuttle table (LST)

- Continuous operation is enabled by offline setup with two processing pallets.

- Pop-up ball transfers facilitate the setting of worksheets and the sorting of parts.

- Microjoint-less processing is achieved.

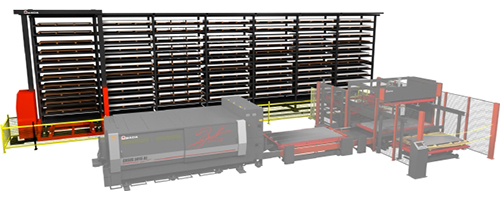

Automated material storage and retrieval system MARS

- The MARS system allows for 24-hour operation.

- The number of rows and columns can be designed freely to meet specific shop spaces.

- The material, inventory and production situations can be managed by process simply and integratedly.

*For Japan domestic market.

For any inquires, please contact local AMADA branch office.