- LCG-3015

- LC-αⅤ Series

- Quattro

- System Upgrade

LCG-3015

Global standard CO2 laser machine

Pursuit of processing thin to medium materials with high speed and productivity

AMADA, a laser machine pioneer, has developed a new global standard laser machine.

The new laser machine adopts a low center of gravity carriage and a latest drive mechanism. These features combine with a high-torque motor and a helical rack system to achieve high-speed processing and cutting acceleration improvement.

- ■ Features(1) : High-speed processing of thin to medium materials

- A low-center of gravity carriage and a latest drive mechanism are adopted to achieve the highest rapid feed rate and cutting speed of the class.

Rapid feed rate: 170 m/min for X and Y axes - ■ Features(2) : High-quality processing

- A new oscillator designed for processing thinner materials is installed to achieve high beam focusability and improve surface roughness.

- ■ Features(3) : Function enabling stable processing

- ECO Cut is an energy-efficient, high-speed oxygen-assisted cutting process. Running cost is reduced by reducing processing time and assist gas consumption.

- ■ Features(4) : Latest functions installed

- The machine is equipped with the function of automatically switching to a power save mode when it goes on standby.

- The internal mirrors are increased in service life.

Processing scene YouTube movies

Material: SPH / Thickness: 6mm

[ Please click here for more detailed movie of the LCG-3015. (YouTube) ]

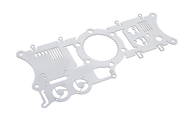

Processing samples

Material: SPC / Thickness: 1.0mm

Specifications

| Rapid feed rate |

Maximum processing size |

Oscillator |

Maximum sheet thickness |

|

|---|---|---|---|---|

| LCG-3015 |

120:120:80 |

3070×1550×100 |

AF3500i-C |

SS:20 |

*For Japan domestic market.

For any inquires, please contact local AMADA branch office.