- LCG-3015AJ

- LC-F1NT Series

- FO-MⅡNT Series

- FO-MⅡ RI3015

FO-MⅡ RI3015

All-around machine for cutting both sheets and pipes/sections

A rotary index unit is mounted on an evolved version of the FO-M II NT machine.

A rotary index unit that allows pipes/sections to be cut at high speed with high accuracy is mounted on an FO-M II NT machine equipped with new technologies. This all-around machine can cut both sheets and pipes/sections. The new all-around machine expands the processing range.

- ■ Feature(1) : Rotary index unit dedicated to FO-M II RI

- Pipes/sections can be cut at high speed with high accuracy.

*Rotary index unit:

Unlike the conventional cantilevered chuck index unit, the rotary index unit can securely clamp the pipe/section. A self-centering chuck, independently driven vertically and horizontally and designed to support pipes/sections near the cutting point, makes it possible to cut the pipes/sections with high accuracy and quality. The regrip function allows the cutting of 6 m standard-length pipes/sections. - ■ Feature(2) : New oscillator AF4000i-B

and high-speed noncontact Z-axis tracking sensor - High-quality, stable processing is accomplished.

- ■ Feature(3) : Oil shot, Cooling Cut, and cutting process monitoring

- Supports for more stable processing

- ■ Feature(4) : Variable-curvature mirror and nozzle changer

- Setup reduction and continuous processing are achieved.

- ■ Feature(5) : Easy operation

- The latest NC control AMNC 3i provides large screen with easy vision and operation with multi-touch method like smart phone, thus dramatically improving operability.

Processing scene YouTube movies

Material: SUS / Thickness: 1.5mm □50×100mm

[ Please click here for more detailed movie of the FO-MⅡ RI3015. (YouTube) ]

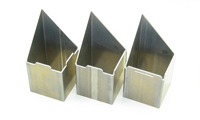

Processing samples

Material: SUS304 / Thickness: 1.5mm φ32mm

Material: SUS / Thickness: 1.5mm

Specifications

| Rapid feed rate(m/min) |

Maximum processing size(mm) |

Oscillator |

Maximum sheet thickness |

|

|---|---|---|---|---|

| FO-MⅡ RI3015 |

80:80:60 |

3070×1550×200 |

AF4000i-B |

SS: (Oxygen) |

Pipe/section processing range

| Type |

RI processing range (minimum to maximum mm) |

Maximum material mass(kg) |

Maximum material length(mm) |

|

|---|---|---|---|---|

| Pipes |

Round pipes |

○ 19~220 |

200 |

6000 |

Square and rectangular pipes |

□ 19~150 |

|||

| Sections |

Equal-legged and unequal-legged angles |

┗ 19~90 |

||

Hot-rolled and cold-formed channels |

┗┛19~150 |

|||

| Note |

The repositioning function allows the cutting of pipes/sections up to 6000 mm in length. (The final grip length of 218 mm cannot be processed.) |

|||

*For Japan domestic market.

For any inquires, please contact local AMADA branch office.