- Punching Machines Top

- EM-ZR Series

- EM-MⅡ Series

- LS-2612E

EM-ZR Series

Fully automatic punching solution machine

Fusion original technologies to achieve processing with high speed, productivity and grade

The EM-ZR series comes with the world's unparalleled drive system, or AC servo direct twin drive, and the ZR turret, a major innovation since the development of AMADA's first numerically controlled turret punch press (NCT).

Parts can be produced not only with high speed and productivity but also with less scratches.

Further with ID tools and elimination of processing limits, the EM-ZR series can perform high-mix low-volume production continuously over 72 hours.

- ■ Features(1) : High quality and high speed processing

- High speed processing with scratch-free bottom surfaces ZR turret and completely flat table

- Easy programming No track dead zones, free tool location

- ■ Features(2) : Stable high quality processing

- Prevention of tool setup mistakes ID tools

- Stabilization of high quality processing Tool condition management

- Elimination of shimming time Automatic die height adjustment

- ■ Features(3) : Automation of tool setup

- Easy creation of nesting data High tool storage capacity

- Reduction of machine downtime Automatic tool changing system

Processing scene YouTube movies

Material: SUS430 / Thickness: 1.0mm

[ Please click here for more detailed video of the EM-ZR series. (You Tube) ]

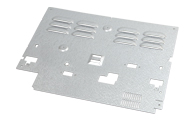

Processing samples

Material: Galvalume steel / Thickness: 1.6 mm

Specifications

| Press capacity |

Maximum processing size |

Hit rate |

Punching accuracy |

Turret |

|

|---|---|---|---|---|---|

| EM-3510ZR T |

300 |

2500×1275 |

500 |

±0.1 |

36(2AI, 4MPT) |

| EM-3510ZR B |

|||||

| EM-3612ZR T |

3050×1525 |

||||

| EM-3612ZR B |

*EM-ZR T: Tool storage specification

*EM-ZR B: Buffer turret specification

*Punching accuracy is based on our data.

*For Japan domestic market.

For any inquires, please contact local AMADA branch office.