- Punching Machines Top

- EM-ZR Series

- EM-MⅡ Series

- LS-2612E

EM-MⅡ Series

New AC servo direct twin drive NCT

Further evolution of best seller machine. Setup time reduction and process integration.

New technologies are added to the EM-NT series with the world's unparalleled AC servo direct twin drive system. The result is faster, more productive, and higher-grade sheet metal fabrication.

An ID tool system and an MPT tapping unit are installed to drastically reduce the setup time and achieve blanking process integration.

- ■ Features(1) : Achievement of stable high speed processing

- Tough and stiff frame structure Highly rigid bridge frame

- Punching of 5' by 10' sheets without repositioning (EM-2612MⅡ,EMZ-3612MⅡ and EMK-3612MⅡ)

- ■ Features(2) : Achievement of high quality processing constantly

- Tool by digital management ID tools

- Prevention of tool installation errors ID Monitor

- ■ Features(3) : Achievement of process integration

- High speed and high productivity Tapping

- Secondary operations are remarkably being efficient. High speed marking

- Deburring work can be done automatically at high speed. High speed deburring

Processing scene YouTube movies

Material: SECC / Thickness: 1.0mm

[ Please click here for more detailed video of the EM-MⅡ series. (You Tube) ]

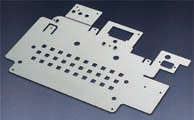

Processing samples

Material: SECC / Thickness: 1.0mm

Specifications

| Press capacity |

Maximum |

Hit rate |

Punching accuracy |

Turret |

|

|---|---|---|---|---|---|

| EM-2510MⅡ |

200 |

2500×1270 |

515 |

±0.1 |

Turret with upper and lower disks of same diameter |

| EM-2612MⅡ |

3050×1525 |

||||

| EMZ-3510MⅡ |

300 |

2500×1270 |

500 |

EMZ (Z turret): |

|

| EMK-3510MⅡ |

|||||

| EMZ-3612MⅡ |

3050×1525 |

||||

| EMK-3612MⅡ |

*Punching accuracy is based on our data.

*For Japan domestic market.

For any inquires, please contact local AMADA branch office.