38th Precision Sheet Metal Technology Fair

Sheet metal parts (101 entries)

- TOP

- Sheet metal parts

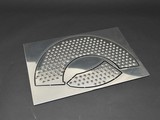

JBOX (Parts045)

Parts045

JBOX

-

・Size: W450 x D300 x H3.16 mm

-

・Accuracy: ± 0.07 mm

・Programming time: 2 min

-

・Processing time: 2 min/quantity

・Quantity: 1

-

・Material: Stainless steel (SUS304)

-

・Thickness: 1.5 mm

-

・Type: Prototype

Process

2D/3D Design

CAD/CAM

Punching

Forming

Strengths