- Welding Machines Top

- FLW-ENSIS Series

- ID-40 Series

- VC-500Ⅱ

FLW-ENSIS Series

Fiber Laser Welding system

Arrival of new era of laser welding

* Partitions are removed for taking photo.

High-speed and high-quality processing realized with multi-functions!

The fiber laser welding system proposed by AMADA realizes high-speed and high-quality welding that cannot be done with conventional laser welding machines.

The new in-house made oscillator solves various problems faced by customers by incorporating AMADA’s unique beam control system. Contributes to higher production processing.

- ■ Features(1) : High-speed and high-quality processing

- "Advantages of Fiber Laser Welding"

- Low distortion/high-speed welding with high energy density

- High-quality welding with CW (continuous-wave) reduces finishing man-hours.

- High heat exchange efficiency reduces running costs.

- ■ Features(2) : ENSIS technology

- "Improvement of response capacity through ENSIS technology"

- Mounting of in-house made fiber laser oscillator [ENSIS-3000 / ENSIS-6000]

- ENSIS technology realizes beam control according to processing applications.

- ■ Features(3) : FLW-ENSIS welding technology

- "Various functions to realize smooth welding"

- AMNC/PC

- TAS (Teaching Assist System)

- ■ Features(4) : Easy setup operation

- "Various functions supporting robot operation"

- TAS (Teaching Assist System) / Setup navigation

- Welding conditions control function (Processing condition files)

- Z indicator

- ■ Features(5) : Digitization of welding process

- "VPSS 3i_WELD"

- Off-line setup of teaching operation

- Data creation without backtracking by simulation function

- Improvement of operation rate through off-line teaching

Processing scene YouTube movies

Material: SUS304 / Thickness: 10 mm

[ Please click here for more detailed movie of the FLW-ENSIS Series. (YouTube) ]

Processing samples

Semiconductor manufacturing equipment cover

Food machinery chute

Sanitary pipe

Examples of system upgrades

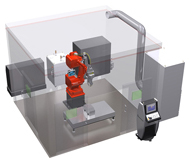

Model1

Robot alone

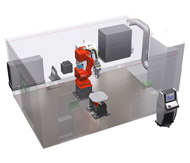

Model2

Robot

+ Positioner table

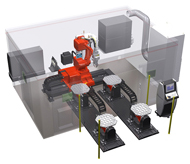

Model3

Robot

+ Positioner table

+ carriage A

Model4

2 Positioner

Shuttle specification

* Model 3 carriage is 1.5 m as standard. (3.0 m / 4.0 m can be selected optionally.)

* Model 5 carriage is 4.0 m as standard.

Specifications

Machine type |

Oscillator |

Maximum melting depth (mm) |

|

|---|---|---|---|

FLW-3000EN |

Fiber Laser Welding System |

ENSIS-3000 |

Iron:6.0 |

FLW-6000EN |

ENSIS-6000 |

Iron:12.0 |

*For Japan domestic market.

For any inquires, please contact local AMADA branch office.

Welding Machines Top| FLW-ENSIS Series| ID-40 Series| VC-500Ⅱ