AMADA Eco Products

All products developed by AMADA are assessed in a variety of categories: energy conservation, resource conservation, recyclable resources, material use restrictions, consideration for the environment at the time of use, rationalization of packaging, and information provision.

Among AMADA’s low environmental impact products, ones that have improved remarkably over previous models based on these assessments are called Eco Products.

Among AMADA’s low environmental impact products, ones that have improved remarkably over previous models based on these assessments are called Eco Products.

FLW-1500MT

The combination of an expanded processing area due to a high-power oscillator and the latest wobbling feature provides wide-range welding, from "smooth welding unique to fiber laser" to "deep penetration welding with minimal distortion using focused beam".

Compared to the previous model, power consumption is reduced by 88.0% and productivity is improved by 45%.

BREVIS-1212AJ

All-around fiber laser machine that meets customer needs for cutting thin-to-thick materials.

Compared to the previous model, power consumption and production cost are reduced by 73.9% and 18.7%, respectively, and the use of lubricant is also reduced by 69.0%.

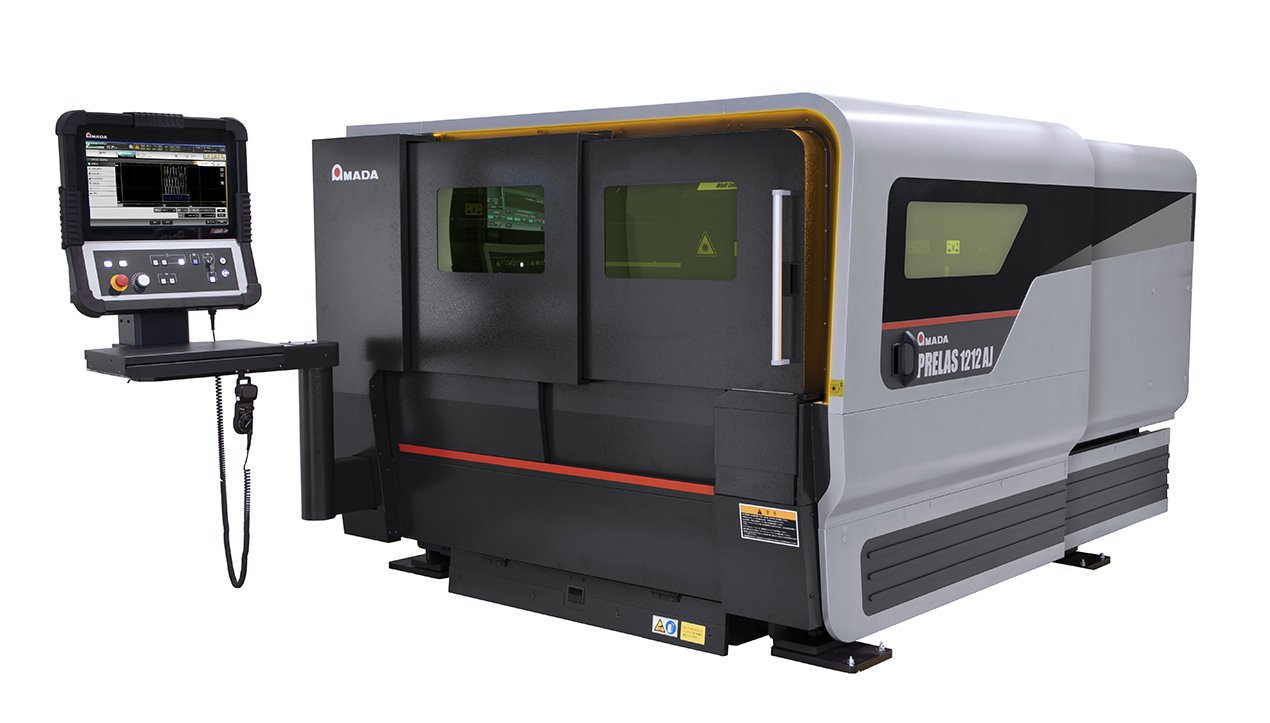

PRELAS-1212AJ

Equipped with a single-mode fiber laser with excellent light gathering capability and a highly rigid frame structure that achieves high precision, making it suitable for ultra-precision machining.

Compared to the previous model, power consumption and production cost are reduced by 85.0% and 30.6%, respectively, and the use of lubricant is also reduced by 69.0%.

REGIUS-AJ series

3-axis linear drive fiber laser machine with unrivaled cutting speed and various support functions

-Power consumption reduced by 62.9% (6kW)/45.2% (9kW)

-Productivity improved by 39.9% (6kW)/65.2% (9kW)

*Compared with the conventional FOL-3015AJ (4kW)

FLW-ENSIS Series

Fiber laser welding system providing high-speed and high-grade process with a variety of functions

-Power consumption reduced by 51%

-Process cost reduced by 37%

*Compared with the conventional YAG lasers

HRB series

HRB is a downacting bending machine equipped with a hybrid drive system. The hydraulic motor runs only during ram operation, which has reduced power consumption. It also suppresses the rise in oil temperature, reducing the amount of oil. (The amount of hydraulic oil is 48 liters with HRB-1003 and 150 liters with HM-1003) Compared with the conventional model, power consumption has decreased by 60.7% and the production cost reduction rate has improved by 13.1%.

VENTIS-3015AJ

VENTIS-3015AJ is a fiber laser machine equipped with "LBC technology" that freely manipulates the beam locus of the fiber laser to create infinite patterns.

Compared with the conventional models, the power consumption has decreased by 33% and the productivity has improved by 38%.

Three functions have improved productivity and enabled high-quality processing and long-time stable processing during operation of the automation system.

EML-AJ series

The fiber laser technology is adopted to the combination machine "EML" to achieve a higher hit rate. In addition, the space-saving automatic tool changer PDC is also furnished with the tool change function and ID tool function during laser cutting.

Compared with the conventional models, power consumption has decreased by 60% and productivity has improved by 16%.

VC-500Ⅱ

VC-500Ⅱ is equipped with digital-inverter control type AC/DC pulse TIG power source.

Chillerless is realized by changing the torch from the water cooled type to the air cooled type and improving the heat dissipation effect of the butted copper plate.

Compared with the conventional model, power consumption has decreased by 11% and productivity has improved by 20%.

HPSAW-310

A super-fast band saw machine created by integrated development of the machine and blade.

Shortening the cutting time has improved the production efficiency dramatically.

Compared with the conventional models, power consumption has decreased by 46% and productivity has improved by 53%.

EG-4010

EG-4010 is equipped with the dual servo press (DSP) mechanism. New concept machine incorporating ergonomics in design and pursuing ease of use.

Compared with the conventional models, power consumption has decreased by 47% and productivity has improved by 11%.

SDE-2017 GORIKI

SDE-2017 GORIKI is a high rigidity type digital electric press machine equipped with AC servo direct drive.

In addition to the slide area which makes it possible to install multi-process progressive tooling, a center gib full guide structure and a high rigidity solid column frame are adopted.

The machine realizes high added value forming and high precision processing. The power consumption is reduced by about 15% and the production cost is reduced by about 29%.

ENSIS-3015AJ

ENSIS-3015AJ is a new-generation laser machine that expands the processing range further. It corresponds to energy saving and multiproduct variable quantity production.

With unique beam control technology, the high-speed and high-precision processing is realized by the low center of gravity carriage, the high rigidity helical gear drive and the wide range processing by low energy.

The power consumption is reduced by about 86% and the production cost is also reduced by 43% (Processing comparison with AL 0.8 mm).

ACIES-AJ series

The latest fiber laser technology is adopted to punch & laser combination machine ACIES-AJ that realizes high-speed processing with less scratch on rear surface by ZR turret / full flat table.

In addition to reducing the power consumption by 78% compared with the conventional models, the machine also reduces the production cost by 16% and noise and improves working environment.

EG-6013AR

EG-6013AR is a bending automatic machine combining a robot optimized for bending works and a high-speed and high precision servo bending machine equipped with a dual servo press (DSP) mechanism.

By integrating tasks that were done by two robots conventionally into one robot, not only the operation speed is improved, but also the power consumption is reduced by 45% and the productivity is improved by 20%.

LCG-3015AJ *Discontinued

LCG-3015AJ is a fiber laser machine adopting our own fiber laser and the latest drive mechanism.

The high-speed and high-precision processing is realized by the low center of gravity carriage and the high rigidity helical gear drive.

By shortening the processing time, the power consumption is reduced by about 86% and the production cost is reduced by about 43% compared with conventional models.

LCG-3015 *Discontinued

LCG-3015 is a global standard laser machine equipped with a new high-grade CO2 laser.

The high-speed and high-precision processing is realized by the low center of gravity carriage and the high rigidity helical gear drive.

By shortening the processing time, both the power consumption and the production cost are reduced by about 30% compared with conventional models (processing comparison with AL 0.8 mm).

LC-C1 AJ series

LC-C1 AJ is a fiber laser combination machine that integrates multiple process and corresponds to multiproduct variable quantity production and short lead time. It reaches the new combination processing area with the lastest fiber laser technology.

By the high-efficiency processing with the fiber combination, the high-speed machining in thin plate processing area and adoption of a laser beam interruption table cabin structure with safety and workability, the reduction rate 81% of the power consumption, the reduction rate 34% of the production cost, the low noise and working environment improvement are realized.

EG series

High-speed and high-accuracy servo bending machine equipped with dual servo press (DSP) mechanism.

Compared with the conventional model, the motor load is reduced and the speed of sudden descent / sudden ascent / bending processing is improved. The power consumption is reduced by 11% and the productivity is improved by 12%.

HG series

HG is a downacting bending machine that adopts a combination of a high-efficiency / bi-directional piston pump and an AC servo motor. It also adopts a new hybrid drive system with two capacity pumps.

It can increase the speed of sudden descent / sudden ascent with the motor as same size as that of the conventional model. It realizes the reduction rate 8.5% of the power consumption and the reduction rate 4.3% of the production cost.

- ※The figures are for HG-8025 compared with the conventional models. The numerical values vary depending on series machine.

FLC-AJ series *Discontinued

HG is a downacting bending machine that adopts a combination of a high-efficiency / bi-directional piston pump and an AC servo motor. It also adopts a new hybrid drive system with two capacity pumps.

It can increase the speed of sudden descent / sudden ascent with the motor as same size as that of the conventional model. It realizes the reduction rate 8.5% of the power consumption and the reduction rate 4.3% of the production cost.

※ The figures are for HG-8025 compared with the conventional models. The numerical values vary depending on series machine.

EM-ZR series

EM-ZR a punching machine realizing high-grade processing with fewer scratches on rear surface with ZR turrets / full flat brush table.

■Energy saving :

It realizes energy conservation by 37% compared with the conventional models.

It shortens the tapping processing time since a tapping station is mounted in the turret of the machine.

By adopting the die up / down method as a countermeasure against scratches on the rear surface, the processing time is shortened compared with the conventional brush levitation method and the power consumption is reduced.

■Resource saving :

By adopting die up / down method instead of separate type of the forming function , the used amount of the hydraulic oil is reduced by 70%.

EM-MⅡseries

EM-MⅡ is a punching machine with MPT tap tool realizing reduction of the setup time and a process integration.

■Energy saving

It realizes energy saving by 31% compared with the conventional machines.

It shortens the tapping processing time since a tapping station is mounted in the turret of the machine.

The high hit rate of the machine realizes the high productivity and 1 clamp processing of 5 'X 10' material (in case of EMZ-3612 MII and EK-3612 MII).

The power consumption is reduced by shortening processing time.

FOL-3015AJ *Discontinued

The latest Laser Cutting Machine with in-house-developed fiber laser oscillator, achieves both high productivity and ecology.

Reduced the power consumption about 80% by new oscillator compared to the current model. Also, laser gas is not in need and lower running costs are achieved.

PCSAW-720

The next generation Band Saw Machine features pulse cutting, achieving high-speed, high-precision, low-noise processing.

Reduced the power consumption about 30% compared to the current model. It also reduces the noise by controlling the chattering vibration of the blade.

ACIES-NT series

This Punch and Laser combination machine has ZR turret and full flat table resulting scratch less on bottom surface with high-speed process.

The power consumption is reduced by about 50% compared with existing model and the air consumption is also reduced by around 40% thanks to high efficient air purge unit.

- ※These figures are on model ACIES-2512. Slight difference on other model.

LC-C1NT series

Punch / Laser combination machine in compact size creating less set up time by various tool configuration(punching, forming & tapping) 35% reduction of power consumption by synchronized control of laser & punch axes compared with previous model.

- ※The figure represents on LC1212C1NT, other models differ slightly

LC-F1NT series *Discontinued

3 axis Linear Motor Drive Laser Machine.

LC-F1NT achieves to reduce about 65% of power consumption by adopting energy-saving mode during standby compared to conventional machines.

Moreover, it also can reduce about 27% of the amount of lubricating oil use by a linear motor drive.

- ※These figures are mentioned about LC-3015NT and somewhat different in case of other models.

AE-NT series

Punching machines equipped with an AC servo single drive.

The AE-NT series achieve an approximate 70% power consumption reduction compared to conventional machines. In addition, it reduces the need to use hydraulic fluid down to zero.

- ※Figures are for the AE-255NT and may differ somewhat for other models.

HD-NT series

(8025/1703L/1703/3503/6006)All 5 models

Hydraulic bending machines equipped with a hybrid drive system composed of a high efficiency bi-directional piston pump and an AC servomotor. Their power consumption is about 50% of that of conventional machines and the volume of oil used has been reduced by approximately 50%. Energy and resource efficient, they significantly reduce environmental impact.。

- ※Figures are for the HD-8025NT and may differ somewhat for other models.

SDEW series

The SDEW series are 2-point servo drive mechanical presses with servo-controlled motors.

They are capable of difficult stamping work through as abundant digital motions and/or strokes, resulting for prototype to mass production.

■Energy-saving :

The motor runs only when the slide activates through a control command. In addition, energy generated from slowing down or stopping the motor is recovered and stored in a condenser to be used as the next drive source. As a result, it consumes less power compared to flywheel-equipped mechanical presses in which the motor is running full-time.

■Resource-saving :

A circulating oil system has been adopted for the sliding section in place of the combination-type wet clutch/ brake used in conventional mechanical presses. As a result, the oil bath system is no longer necessary, so less lubricant is consumed.

SDE Series

The SDE series are servo drive mechanical presses with servo-controlled motors.

They are capable of difficult stamping work through as abundant digital motions and/or strokes, resulting for prototype to mass production.

■Energy-saving :

The motor runs only when the slide activates through a control command. In addition, energy generated from slowing down or stopping the motor is recovered and stored in a condenser to be used as the next drive source. As a result, it consumes less power compared to flywheel-equipped mechanical presses in which the motor is running full-time.

■Resource-saving :

A circulating oil system has been adopted for the sliding section in place of the combination-type wet clutch/ brake used in conventional mechanical presses. As a result, the oil bath system is no longer necessary, so less lubricant is consumed.

EML-NT Series *Discontinued

The EML-NT series are "intelligent" punch/laser combination machines with AC servo direct twin drives on the punching drive.

In addition to oil free and energy saving features, the braking energy from RAM control is recovered and stored in a condenser, to be reused as energy for RAM acceleration. As a result, the EML-NT series offers significantly higher performance than conventional combination machines, while also saving energy and natural resources.

Cutting fluid

16 types in all: MU601/ MU801 / CMW / RS /R / RL / SD / GR501 / SA / CTB / DP / AML-1 / AML-2 / AML-3 / AML-4 / AMADABARICOOL

These cutting fluids are free of chlorine, which generates dioxin during thermal recycling processes. They are also free of chemical substances controlled by PRTR* notifications.

※Pollutant Release and Transfer Register

Contact for repair/recovery of AMADA products and our corporate activities.